Freymond Lumber is a busy, well-established family-run lumber mill tucked in a scenic valley at the south end of Bancroft. The Freymond brothers, Dan and Lou, have three businesses operating in this location. First, they have Freymond Lumber. This business sells lumber to retail and wholesale customers, and also sells lumber for log homes. Then they have Freymond Logging. This business provides forestry services, such as log sawing, pulpwood and timber harvesting, tree marking, boundary line running, standing timber purchases for high and low quality trees, and all other forestry management needs. Last but not least is Freymond Wood Products, which buys lower quality roundwood from logging companies and produces chips for various markets. Corporations use the wood fibre to make paper, OSB, particle board, newsprint or cardboard.

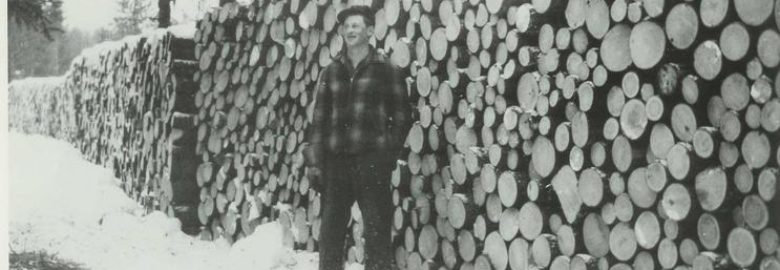

Freymond Lumber was started by their father Peter and uncle Renee. The Freymond family came to Canada from Switzerland in 1929 to a farm in Dungannon Township. It was a poor farm and the family nearly starved. The only money they made was from cutting timber. Peter and his brother Renee moved into the lumber business, first cutting logs for someone else to process. In 1946, they set up their own sawmill first in Monteagle Township. They then opened a mill where Jan Woodlands is now. They moved to their present site at 2287 Bay Lake Road in 1956. It was part of a farm that runs on both sides of Highway 67 and occupies 250 acres.

The first mill was powered by diesel, and the second was powered by electricity. The third mill, installed in 1981, is powered by hydro electricity. They put in a wood-processing chipper in 1995. As a result of the three operational expansions to its Bancroft facility, the mill is now able to handle both the softwood and hardwood species found in the area, all adult-growth lengths, as well as pulp loads and woodchips. Having that capacity has allowed Freymond to meet the needs of its customers. “We are constantly having to change the products we offer. Different types of logs, different lengths of cut, and different sizes of stacks,” says Vice-President, Lou Freymond. “To keep our customer base, we’re constantly making whatever adjustments are necessary.”

They are one of the largest employers in the Bancroft area, with 45 full time employees and probably the same amount of loggers contracted in the bush harvesting. Freymond produces around seven million board feet of lumber annually, of which 70% is hardwood and 30% is softwood. The chipper produces 75,000 tons a year. The grading and recording is done using a voice recognition system, as is the sawing. This makes grading and recording quick and efficient, thereby ensuring timely payment to contractors and landowners. The wood comes from a 60 mile radius, 60% from crown land and 40% from private land. As much as possible, Freymond Lumber ensures that their cutting practices are above standard, with less than three per cent stand damage on both private and crown lands. Future plans may include installing a biomass plant on site to make hydro either for the plant or for the area, as hydro rates are very high.